The goal of this project is to create a device which can reliably and efficiently transmit heat away from a small gasoline engine and radiate it safely into the atmosphere. Heat removal is a vital component of engine design. Since many small engines serve stationary purposes with little to no air flow, it is necessary to design a device which removes heat reliably and consistently. A heat pipe will serve this purpose.

Wednesday, August 17, 2016

Sunday, May 29, 2016

Project Overview

Project Overview

Fundamentally, a heat pipe is a device that transmits thermal energy from one point to another. It accomplishes this both through the thermal conductivity of the pipe and through the phase transition of fluid within the pipe. Heat pipes can be used in any application that requires the transfer of heat, though they are used extensively for cooling applications such as CPU heat management, spacecraft radiators, and certain internal combustion engines.

Source: Benchmark Reviews

An example of a complex heat pipe with radiator fins for computer heat management.

This project will focus on the ability of heat pipes to remove excess heat from a device and radiate it into the atmosphere. In this case, a heat pipe will be designed to remove heat from a small gasoline engine and safely transmit it to a heat sink which will radiate the heat into the atmosphere. This process is especially applicable to the Wankel rotary engine which has notorious problems due to uneven heating of the ignition chamber. Since many small gasoline engines serve stationary purposes with no air flow to help in cooling, heat pipes are a practical method of removing heat from the engine reliably without requiring any extra work.

Source: Cars in Trend

A diagram that displays the workings of a Wankel engine. Note that the combustion always takes place on the right side of the combustion chamber which causes uneven heating.

Source: Cars in Trend

A diagram that displays the workings of a Wankel engine. Note that the combustion always takes place on the right side of the combustion chamber which causes uneven heating.

A heat pipe is a sealed pipe made from a thermally conductive material. Inside, it contains a working fluid which evaporates at the heat source (evaporator) and condenses at the radiator (condenser). In this project, a wick will be used to absorb condensed water on the condenser side and transmit it back to the evaporator side of the pipe through capillary motion. Some heat pipes use gravity or even centrifugal force to accomplish this, however a wick enables the heat pipe to lay horizontally which best suits the application in this project.

Source: Overclock

A diagram that shows the basic cyclical mechanisms of a heat pipe.

Source: Overclock

A diagram that shows the basic cyclical mechanisms of a heat pipe.

The goal of this project is to create a working heat pipe that can effectively reduce the temperature from a heat source and effectively transmit it into the atmosphere.

Sources

Wu, W., Lin, Y., and Chow, L., "A Heat Pipe Assisted Air-Cooled Rotary Wankel Engine for Improved Durability, Power and Efficiency," SAE Technical Paper 2014-01-2160, 2014, doi:10.4271/2014-01-2160.

Thursday, May 26, 2016

Week Nine Update

Week Nine Update

Pipe Sealing

This week, the heat pipe was sealed securely. Sealing the pipe has been one of the largest issues in this project. During every test prior to this, a leak developed that allowed liquid water and vapors to escape the pipe, thus reducing efficiency. This week, we tripled the amount of teflon tape on the threads of the cap and sealed the cap as tightly as possible. We then added additional teflon tape to the joint between the cap and the pipe. This proved to sufficiently seal the pipe and no leaks occurred. The increase in efficiency is apparent in figure 2 below. The pipe was set up like the other previous tests. The evaporator end was at the bottom receiving the heat. The condenser end was at the top away from the heat source. There were

three sensors. One at the evaporator end, middle and condenser end (figure 1)

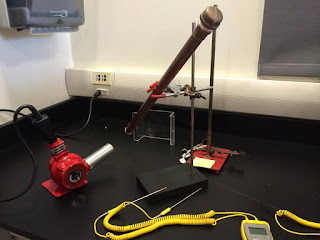

Figure 1: Set up of 4th test

Test Four Results

Figure 2: Result of the 4th test

This test shows increased efficiency when compared to the last test. Once a high enough temperature is reached at the evaporator end, that end of the pipe actually begins to cool as water transfers heat to the condenser end and the radiator fins. This represents the cooling of the small engine.

Wednesday, May 25, 2016

Budget

Table:

Required Materials

Category

|

Cost

|

1” x 2’ Copper Pipe

|

$11.63

|

Aluminum Sheet

|

$12.45

|

Copper Cap

|

$2.62

|

Copper Adapter

|

$7.79

|

Brass Threaded Cap

|

$10.64

|

Distilled Water

|

$0.00

|

Epoxy Resin

|

$3.24

|

Thermal Patse

|

$4.12

|

Sponges

|

$2.16

|

TOTAL

|

$54.65

|

In the weeks following our initial materials acquisition,

the only several other expenses were made one was to get sponges to use as a

wick for the heat pipe, but those were already calculated for the final

report. The next expense is to get

thermal paste and epoxy for the heat pipe was $7.36 raising the total cost of

this project to $54.65. There should be no other expenses until the completion

of the project.

Wednesday, May 18, 2016

References

References

[1] C. E. Heuer, “The Application of Heat Pipes on the Trans-Alaska Pipeline,” U.S. Army Corps of Engineers, Hanover, NH, Special Report 79-26, 1979.

[2] W.

Wu, Y. Lin and L. Chow, "A Heat Pipe Assisted Air-Cooled Rotary Wankel

Engine for Improved Durability, Power and Efficiency", SAE Technical Paper

2014-01-2160, 2014.

[3] Single Cylinder OHV Air-Cooled Engines, Briggs

& Stratton Corp, Milwaukee, WI, 2009.

[4] G.

M. Grover, “Evaporation-condensation heat transfer device,” U.S. Patent 3 229

759, Jan. 18, 1966.

[5] SMT Component & Assembly, TutorialsWeb,

Available: http://www.tutorialsweb.com/smt/smt.htm

Timeline

Table 1: Timeline: The yellow highlights mark the progress of the group until recently.

Task

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

Research

|

x

|

x

|

x

|

x

| ||||||

CAD Designing

|

x

|

x

| ||||||||

Material Acquisition

|

x

| |||||||||

Heat Pipe Assembly

|

x

|

x

| ||||||||

Theoretical Calculations

|

x

|

x

| ||||||||

Testing

|

x

|

x

|

x

|

x

| ||||||

Data Analysis / Experimental Calculations

|

x

|

x

|

x

|

x

|

x

| |||||

Heat Sink Assembly

|

x

|

x

| ||||||||

Final Report Preparation

|

x

|

x

|

x

|

x

|

Timeline Update:

Week 7 was just completed and the pipe assembly and testing

is going on as planned for the most part, the process has been slowed because

there is also a critical defect in the heat pipe. Heat sink assembly has also been pushed to

week 8, and will be completed before the lab session. Testing will continue,

but the pipe is not working with the efficiency originally calculated. The

reason for slow progress of optimal results is due to a small leak at the

threaded end of the pipe. There is a small gap that leaks water and pressure

and in such a delicate system even the smallest gaps can negatively impact

results. So this week will be focused on solving the problem with the leak, and

assembling the heat sinks.

Week Eight Update

Radiator Fin Attachment

To attach the fins, first the surfaces of the pipe and each fin had to be prepared. Both the pipe and the fin surface were cleaned with scotch brite and methanol to remove any oil or impurities. The surface of the copper pipe was also roughened to give the epoxy more surface area to adhere to. The bases of the fins were first coated with thermal paste, then, they were held into place and secured by rubber bands. Once this was complete, epoxy was applied to the two edges of each fin. Once the epoxy for one fin had set, the next fin was begun. It was discovered that a slight bend in the middle of the bonding surface of each fin created a better fit to the rounded surface of the pipe. The rubber bands were removed after 24 hours once the epoxy had fully cured.

Figure 1: Top isometric view of the fins

Figure 2: Isometric view of the fins

Figure 3: Side view of the fins

The goal for week 8 was to get the pipe completely sealed. During the lab, the group brought the pipe over to the machine shop and got it tightened. There was, however, a little miscommunication in the group and so the pipe was only tightened but the PTFE tape was not replaced. The pipe was then tested without having the PTFE replaced and the following is the result from the test.

Test number 3

The pipe was tested again and the figure below plot out the data recorded. The difference here is that there are fins attached to the condenser end. The figures ( 4 and 5) below show the set up and the plotted result.

The result, however, does not seem to be much different than the result from week 7. The condenser also barely increased in temperature. Not surprisingly, the pipe was also leaking at the time of testing (figure 6 bellow). The team did not do a good job of securing the pipe and so the reason as to why the pipe does not work is still a mystery and the group cannot move on until the pipe has been secure tightly. The leak, however, did seem to be less than that of week 7. If the group could add more layers of PTFE and tighten the cap more then maybe the cap will be secure and result might change.

Figure 4: Set up to test the heat pipe

Figure 5: Result of test 3

The result, however, does not seem to be much different than the result from week 7. The condenser also barely increased in temperature. Not surprisingly, the pipe was also leaking at the time of testing (figure 6 bellow). The team did not do a good job of securing the pipe and so the reason as to why the pipe does not work is still a mystery and the group cannot move on until the pipe has been secure tightly. The leak, however, did seem to be less than that of week 7. If the group could add more layers of PTFE and tighten the cap more then maybe the cap will be secure and result might change.

Figure 6: Leakage of the pipe.

Week Seven Update

Radiator Fin Construction

Since the size of the radiator fins could not be reliably calculated using mathematics, it was decided to use the size and shape of the radiator fins in the CAD model. It was also decided that the material for these fins -- aluminum-- should be used for its low price and relatively high thermal conductivity.

Figure 1: Cut out of the fins

Since the sheet aluminum is very thin, it was decided that attaching the fins to their pipe would be unrealistic and would not transmit enough heat to make a difference in the performance of the pipe. Therefore, it was decided to cut the fins two at a time. Two fins would be connected together and the bent into a "V" shape with a flat bottom. Several of these "V" shapes would then be attached to the pipe with thermal paste and held into place with epoxy. This attachment will be done next week. During this week, the fins will be cut, sanded, and bent into shape.

Second Test

Figure 2: Result of the 2nd test

The heat pipe underwent a second, more thorough test to determine its feasibility as a heat pipe. The results of this test would largely dictate if the project was heading in the right direction. The results, as shown above, show a steady increase in temperature on the respective ends of the pipe as time progressed. Most importantly, the increase in temperature readings on the condenser end of the pipe shows that there is indeed a transfer of heat from the evaporator end of the pipe to the condenser end of the pipe via the wick. This is the basis of the working of the heat pipe and as per the data collected, the project will prove to be a success.

Leakage

The result was of the pipe was not as it needs to be. The temperatures at the evaporator end and condenser end are too far apart. The reason for the condenser barely going up in temperature could very much be the leakage that happened during the test.

Figure 3: Leaked water on the table after the test.

As shown from figure 3, it is a bit blended into the background but there was a leakage from the pipe during the test. This is due to the brass cap not twisted tight enough. The thread on the pipe had a few layers of PTFE and the cap was twisted on with the wrench but it was not enough.

As for conclusion, the team decided to add more PTFE layers and twist the cap on more tightly to make sure the the cap will be completely air tight. If the group could get the cap securely on, the result could be alter drastically. However, it could be that the leakage is not the main reason why the pipe does not work. This is not completely clear until this problem of the cap is fixed and tested for another time. If the water does not leak anymore but the pipe still does not work then the team has to try and diagnosed the problem.

Wednesday, May 4, 2016

Week Six Update

Modification of the pipe

From the first test last week, the pipe definitely need more testing and modification. This week, the pipe received some changes to see if a certain alteration in an element will affect the amount of heat transferred. The wick was removed from the pipe. When opening up the pipe and taking out the wick inside, there was a blue/green color to the wick.

As seen from figure 1 above. The outside of the wick has adopted a greenish color. However, figure 2 shows that the inside of the wick is normal. A member of the group made the observation and made an interesting hypothesis that the greenish color could be due to the oxidation of copper. Two facts that could back this hypothesis up is that the outside of the wick was the only thing that touched the copper pipe's inside. The fact that the copper is oxidizing is not ideal because any chemical reactions in the pipe could change the pressure of the pipe and introduce impurities into the working fluid. The pipe was then left to dry.

An alternate designed that need to be tested is the pipe without the wick. This will reveal if the designed wick was doing what it was supposed to do or not. This time, the boiled distilled water was added like last time. The threaded end of the pipe had to wrapped around with PTFE tape and then the water was poured in. The cap was then put on and tightly sealed. This get the pipe all ready for testing in lab during this week.

From the first test last week, the pipe definitely need more testing and modification. This week, the pipe received some changes to see if a certain alteration in an element will affect the amount of heat transferred. The wick was removed from the pipe. When opening up the pipe and taking out the wick inside, there was a blue/green color to the wick.

|

| Figure 1: The outside of the wick. |

|

| Figure 2: The inside of the wick |

An alternate designed that need to be tested is the pipe without the wick. This will reveal if the designed wick was doing what it was supposed to do or not. This time, the boiled distilled water was added like last time. The threaded end of the pipe had to wrapped around with PTFE tape and then the water was poured in. The cap was then put on and tightly sealed. This get the pipe all ready for testing in lab during this week.

|

| Figure 3: The pipe being wrapped in PTFE tape |

|

| Figure 4: Pouring the boiled distilled water into the pipe |

Creation of Radiator Fins

Wednesday, April 27, 2016

Week Five Update

Week Five Update

Insertion of Working Fluid

This week, the group finished the first heat pipe prototype to be tested in lab. It contains roughly 30mL of distilled water as a working fluid and a sponge interior as a wick, but does not yet have a radiator. It was decided that the pipe should be tested without the radiator first so that the effects of the extra heat fins can be measured and used for calculations to determine the optimal shape, orientation, and amount of radiator fins. The amount of working fluid and type of wick are also likely to be modified after testing. This is the first working model, so future changes are expected.

|

| Figure 1: Pouring boiled distilled water into the pipe |

Filling the heat pipe with working fluid is more complex than it initially sounds. To avoid excess pressure build-up, the material of the pipe, wick, and working fluid most all be non-reactive. Additionally, the amount of working fluid must be carefully determined and inserted correctly so that the heat pipe does not explode while it is heated. To accomplish this, distilled water is boiled before it is poured into the heat pipe. The boiling water produces steam which pushes excess oxygen out of the pipe. The pipe is sealed using a threaded cap with polytetrafluoroethylene tape to lubricate and seal the threads. Because the pipe is sealed while gaseous water is present to evacuate air from the pipe, when it cools, the pipe will have a pressure below 1 atm. This low pressure within the pipe will lower the boiling point of the working fluid. A lower boiling point is ideal in this situation because it allows for easier vaporization of the working fluid during pipe operation which increases heat transfer efficiency. It is also ideal because when the distilled water boils, it will not increase the pressure of the pipe above atmospheric pressure. This minimizes risks of leaks developing or catastrophic failure in the form of a pipe rupture.

|

| Figure 2: This shows the sealed pipe with threaded cap and polytetrafluoroethylene tape. |

Leak Discovery and Repair Plan

During week five lab, a leak was discovered in the seal between the bronze cap and the copper pipe. Liquid water was able to seep through the seal which also means that the pipe is not air-tight. This is concerning because it means that the inside of the pipe is now at 1 atm of pressure. If the pipe is resealed and then heated, the internal pressure of the pipe will rise above 1 atm of pressure and present a risk of explosion. Further research will be conducted to determine how much pressure the pipe will be able to handle before it fails.

To fix the seal, it will be necessary to remove the cap, apply another layer of polytetrafluoroethylene tape, and then use a large wrench to tighten the cap as much as possible rather than tightening it by hand. Such a wrench will need to be acquired somehow.

Calculating Maximum Internal Pressure

First Test

In class for week 5. The heat pipe went through its first test. The set up was as followed.

|

| Figure 3: The set up for the first test |

The pipe was put in a diagonal position with one head close to the heat gun while the other head away from the heat gun. There was three heat sensors that was attached to the pipe. One at each end and one in the middle. The purpose of these sensors were to keep track of the temperature change and to see if the pipe was transferring heat and if so, how effectively? The following were the temperature at the initially for the pipe.

|

| Figure 4. Temperature at the condenser end initially |

|

| Figure 5. Temperature at the middle of the pipe initially |

The following are the time of the pipe after the heat was applied constantly for 8 and a half minutes.

|

| Figure 6. Temperature at the condenser end after 8.5 minutes |

|

| Figure 7. Temperature at the middle of the pipe after 8.5 minutes |

First Test Results

The lack of consistency in the evaporator end curve is due to the fact that the thermal probe was held by a person rather than by tape. The tape would have melted at those temperatures. The fact that the middle temperature probe begins to decline is probably due to the fact that the tape loosened due to the heat and caused the probe to shift.

In future tests, these issues will be considered so that more accurate test results can be acquired. Additionally, variables such as removing the wick and introducing radiator fins to the condenser end will be introduced.

Subscribe to:

Comments (Atom)